Pikalba

Hyperion GEN3 Propulsion EVA Foam Filling Core 16mm Pickle Paddle with Ben Johns Edition Pickleball Paddle Racket UPA-A pprove

Hyperion GEN3 Propulsion EVA Foam Filling Core 16mm Pickle Paddle with Ben Johns Edition Pickleball Paddle Racket UPA-A pprove

Couldn't load pickup availability

SPECIFICATIONS

Model Number: FANSU 16.00mm GEN3

Origin: Mainland China

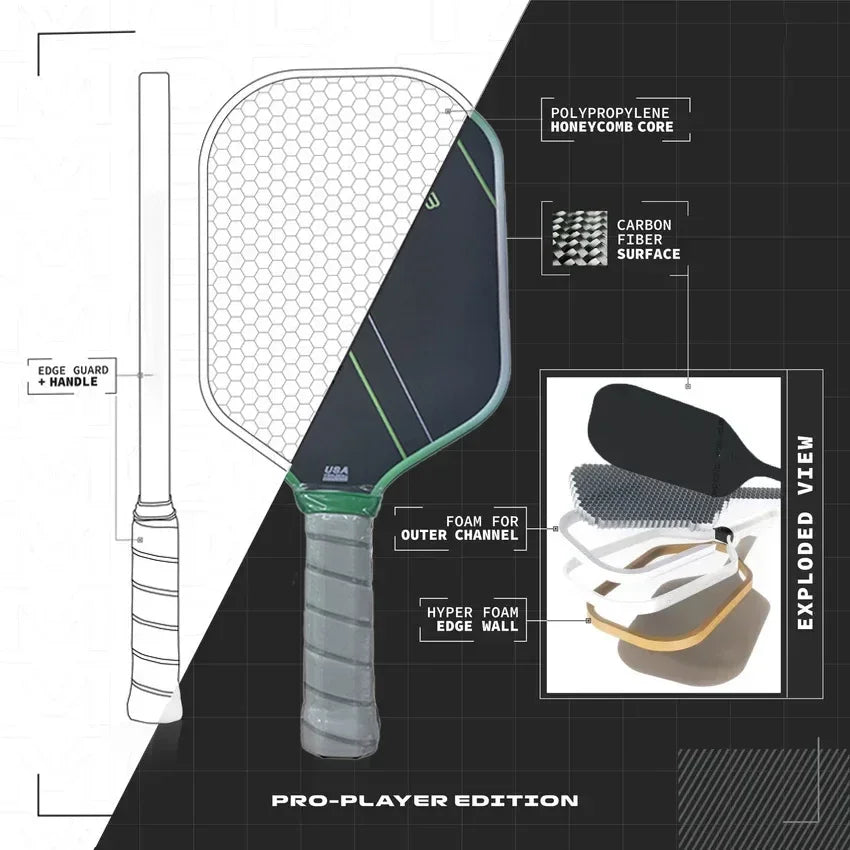

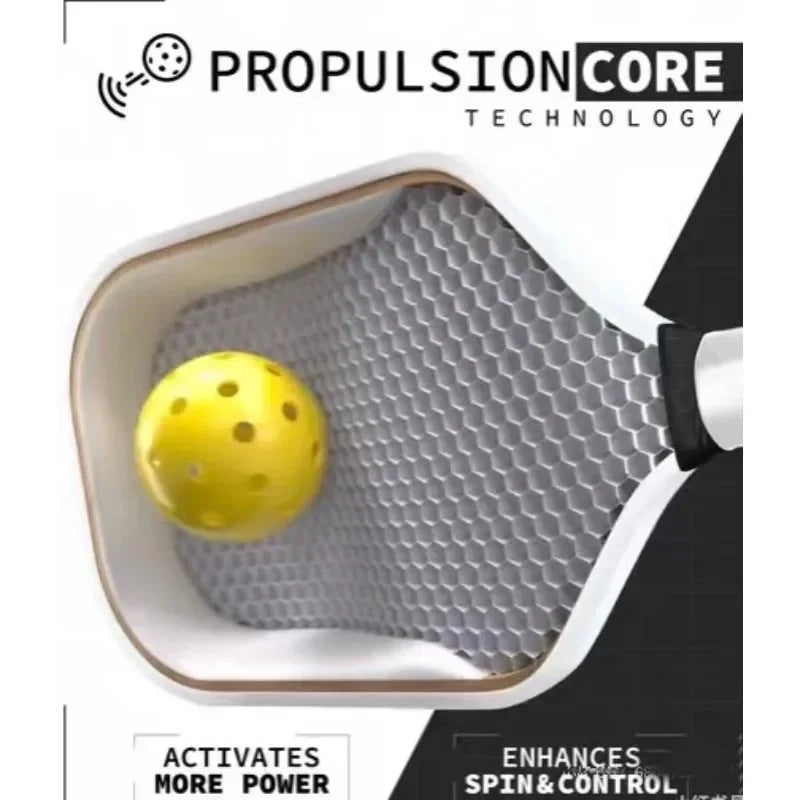

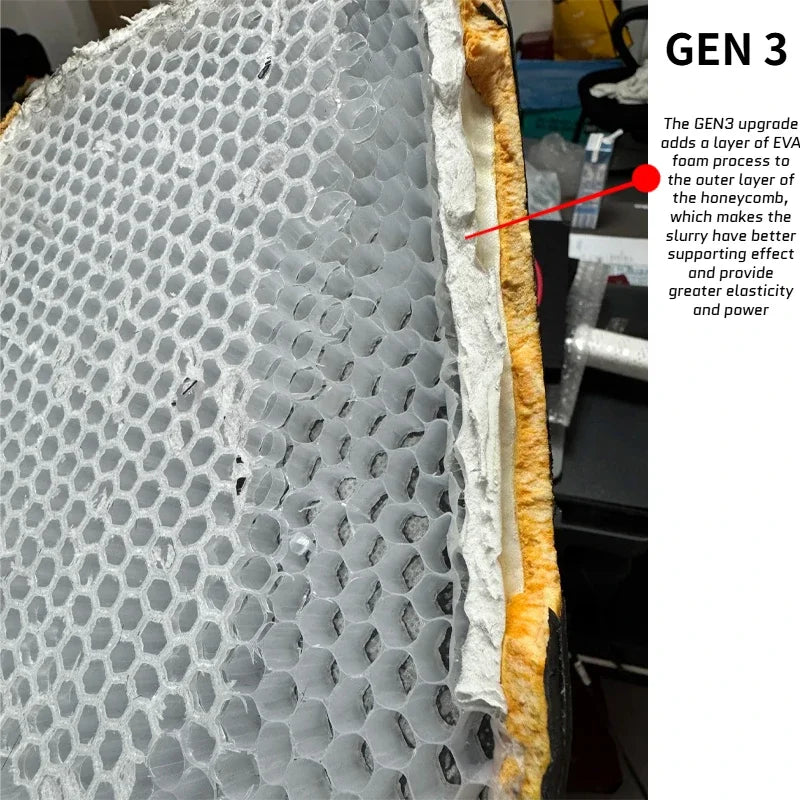

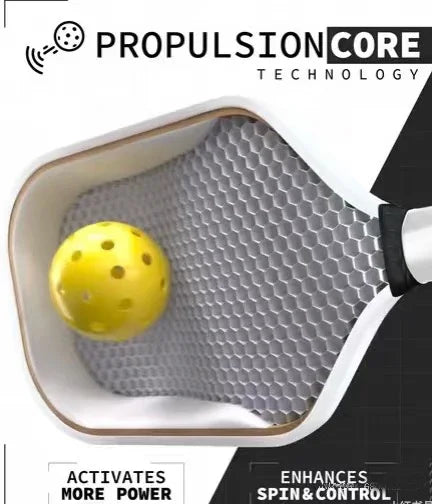

Built with a focus on solidity, Gen3 paddles were engineered to play the same every time you take the court. The enhanced stability in each paddle allows for precise shot placement and improved handling. Feel the confidence to dominate every rally with a new and improved core, combined with Propulsion Core technology to deliver the perfect blend of power and control. Gen3 technology enhances the Perseus' signature sweet spot and Charged Carbon Surface to deliver exceptional energy return. The Gen3 paddle line adheres to the official performance standards of pickleball and is USAPA certified, empowering you to unleash your full potential.

Product Features:

Power Meets Precision with T700 Carbon Fiber:

The Hyperion 3s pickleball paddle features advanced T700 carbon fiber,

delivering exceptional durability and a powerful response. Ideal for

players seeking a balance of strength and finesse with every shot.

Enhanced Play with Thermoformed Construction:

Designed with thermoformed carbon fiber, this paddle is built for

lasting stability and consistency, allowing you to take control with a

solid, reliable feel in every match.

Gen 3 Technology:

As a Gen 3 pickleball paddle, the Hyperion 3s brings innovative design

and performance enhancements for players looking to elevate their game.

Perfect for professionals and enthusiasts alike who prioritize a modern,

responsive paddle.

Precision Engineering with Foam-Injected Core:

Featuring a foam-injected core, this professional pickleball paddle

maximizes control and vibration dampening, giving players added comfort

and pinpoint accuracy, especially during intense rallies.

Built for Versatility with a 16mm Thickness:

The Hyperion 3s paddle's 16mm thickness supports both control and

versatility, making it suitable for diverse playing styles. With a

propulsion core design, it ensures an optimal balance of power and

touch, perfect for competitive play.

Size:418mm*190mm*16mm

After the carbon fiber plate is glued to the honeycomb, it is put into the mold for thermoforming.

After 25 minutes of thermoforming, we can get a semi-finished 360-degree GEN3 pickleball paddle.

Next, we print the surface pattern. Assemble edge guard strips and GRIPS. We end up with a finished GEN3 pickleball paddle.

When glass fiber is added to the surface of the carbon fiber plate, paddle will have more control and spin in use.

The EVA foam filled propulsion core will make the paddle have more powerful resilience.

GEN3 paddle will give you a great experience in pickleball games.

16.5*7.5 inch fan-shaped top and 140mm has lower wind resistance and is suitable for backhand forward attacks,

Surface materials are commonly divided into three categories: glass fiber, carbon fiber, and Kevlar

Among them, carbon fiber is divided into several categories based on strength, namely T300, T700, T800, T1000, 3K, 12K, and 18K

Step4 Thermoforming

Place the pre formed honeycomb core and